Cased Hole

Cased Hole

Our IP Cased Hole suite of modules give you the tools to make well informed decisions quickly and efficiently based on data gathered all in one place.

Analyze and review the condition of downhole casing using our Casing Inspection module.

Make fast and well informed operational decisions about the cement job using our Cement Evaluation module. Identify poorly cemented regions and take immediate action.

Determine behind casing reservoir water saturation using the Sigma Analysis modules

With the Production Logging module, you only need one module to organize, edit and analyze all your PL data. Take advantage of IP's end-to-end integration by combining and refining open and cased hole interpretations side by side.

Explore the modules

included in this toolkit

Ross Brackenridge

IP Product Champion

“No longer do we need separate software packages to analyse open hole and cased hole data. With the introduction of IP’s Carbon Oxygen module, IP now has a wide range of Cased Hole modules which can be used to interpret all data types throughout the whole lifecycle of the well in one package.”

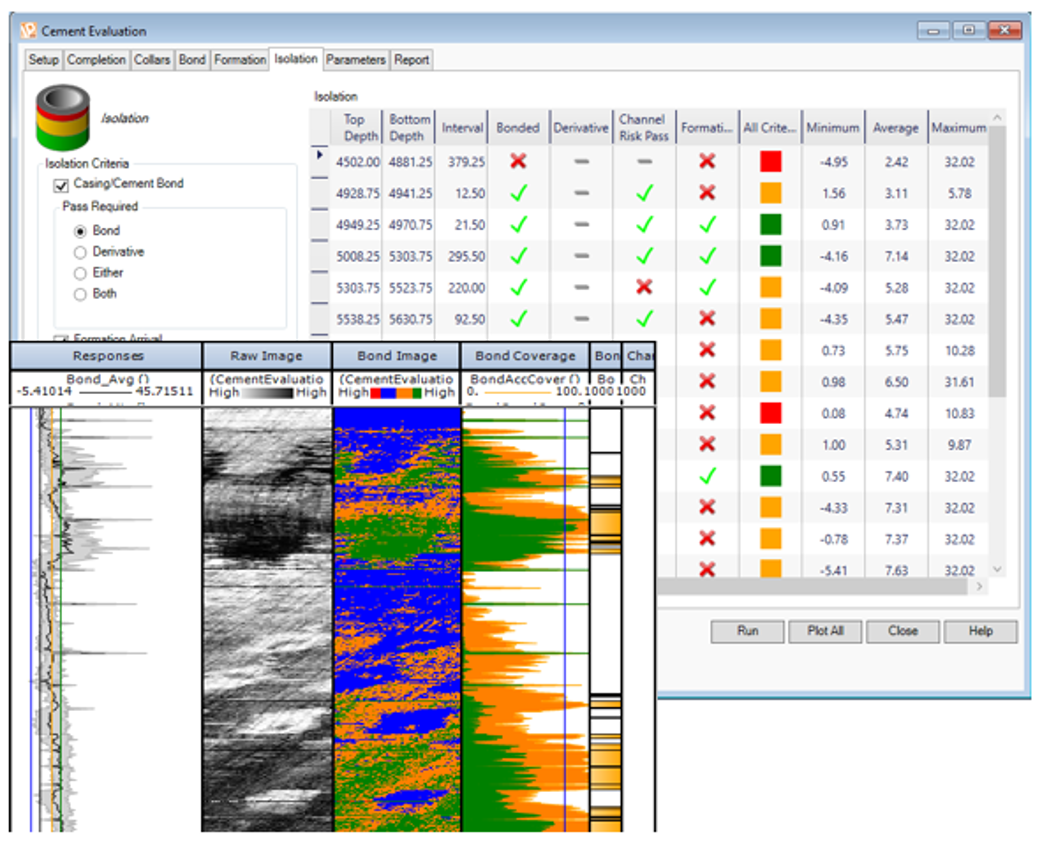

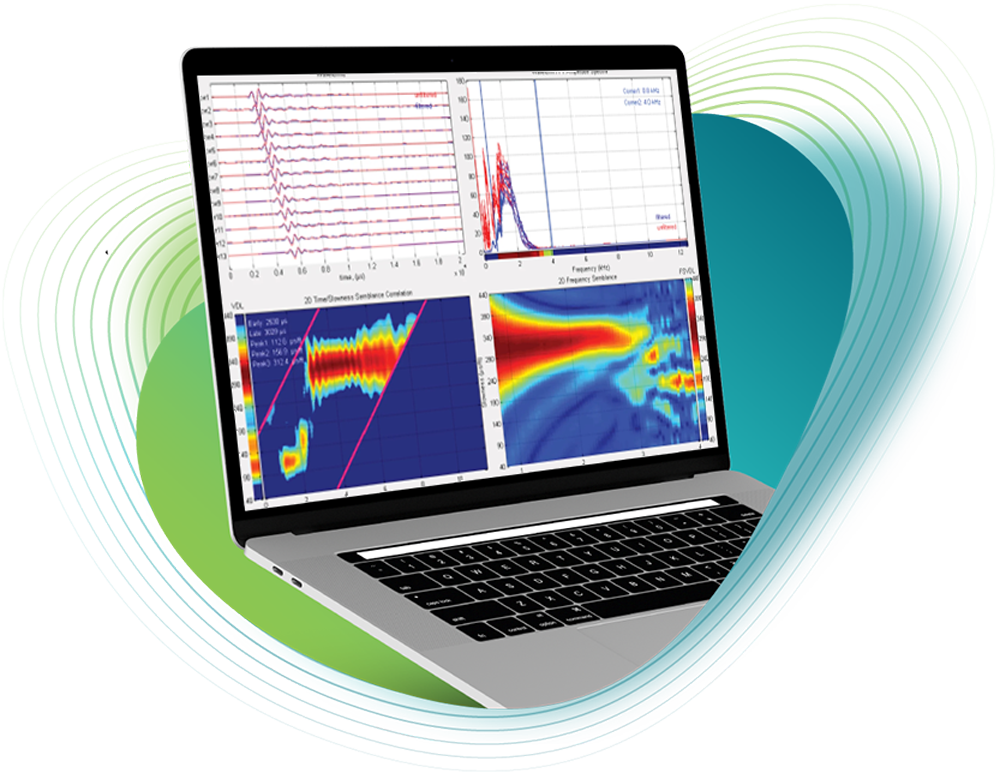

Cement Evaluation

Make fast, well-informed decisions on cement bond quality for safe and efficient drilling, production and abandonment. Cement Evaluation independently assesses data from all major tool types, from traditional Cement Bond Log equipment to advanced ultrasonic devices.

Its detailed, user-friendly isolation report makes it clear which zones are most likely to provide annular hydraulic isolation.

- Enhance wellsite safety with optimal decision making

- Save hours over manual methods

- Combine and compare bond results with open hole data

Pictured: The Bond Focus Plot which allows users to interactively adjust the cut-off parameters for fluid and cement and see the results change real-time

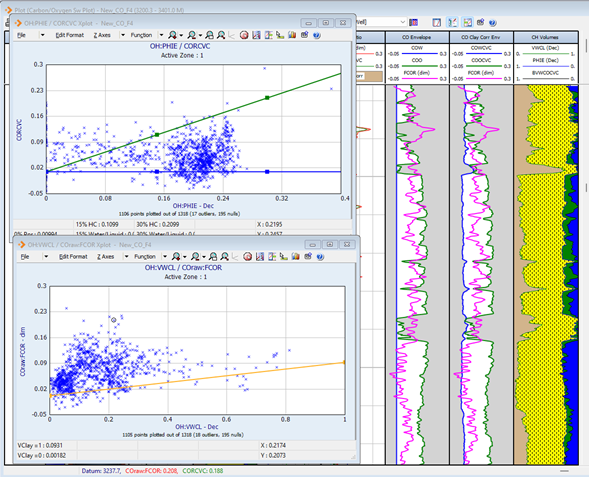

CO Sw Analysis

Monitor behind casing fluid saturations in reservoirs with low, mixed or unknown water salinity. When reservoir water salinities are high, pulsed neutron data can be analyzed used in IP’s Sigma analysis module (part of the IP Interpretation license) however, when salinities are low, mixed or unknown tools are logged in Carbon-Oxygen mode or Inelastic modes. This module imports the Carbon-Oxygen or Inelastic data from the Pulsed Neutron tools alongside open hole data such as Porosity and Clay Volume. Once the logging environment and the tool response charts are defined, a cased hole Water Saturation (Sw) or Gas Saturation (Sg) is calculated.

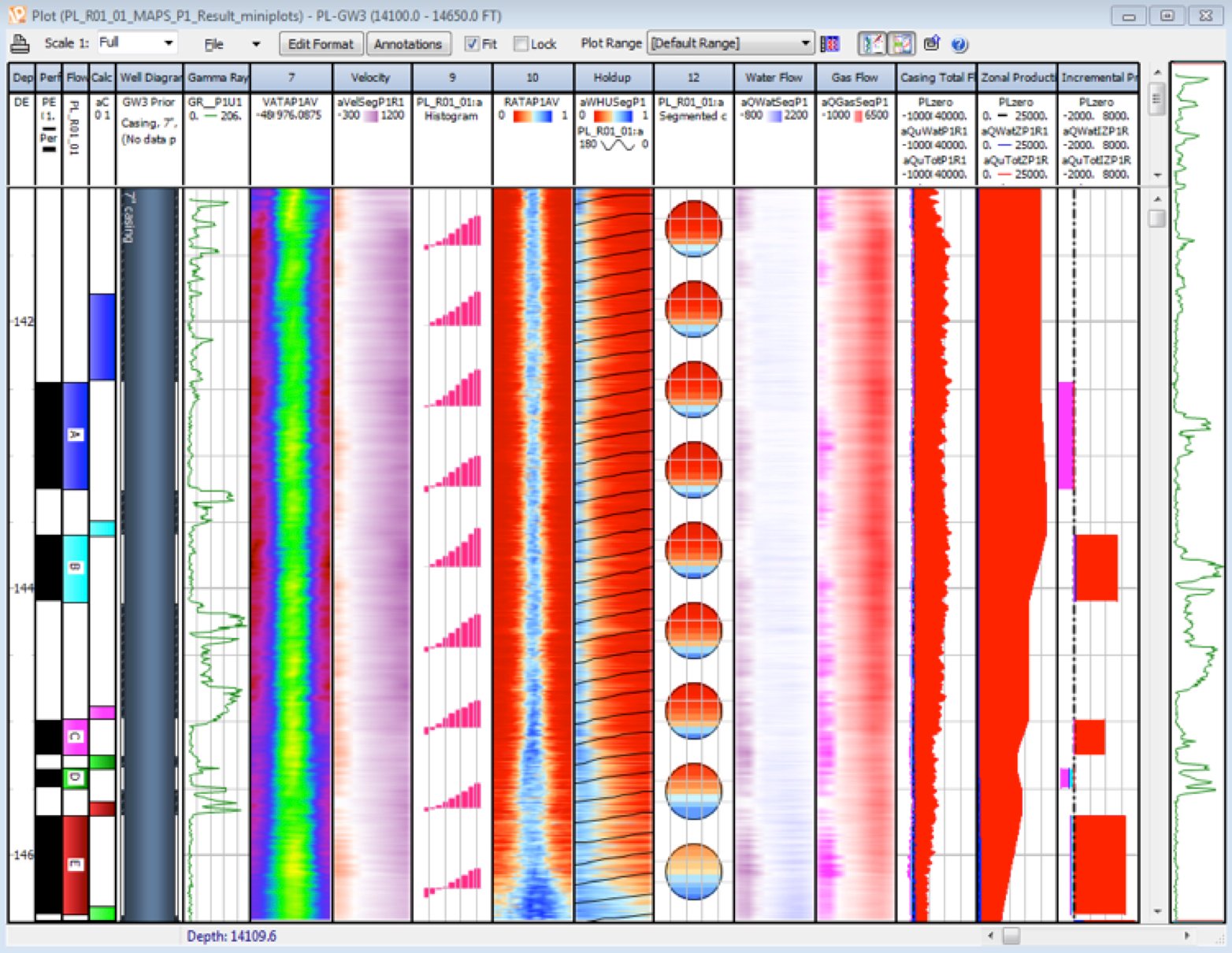

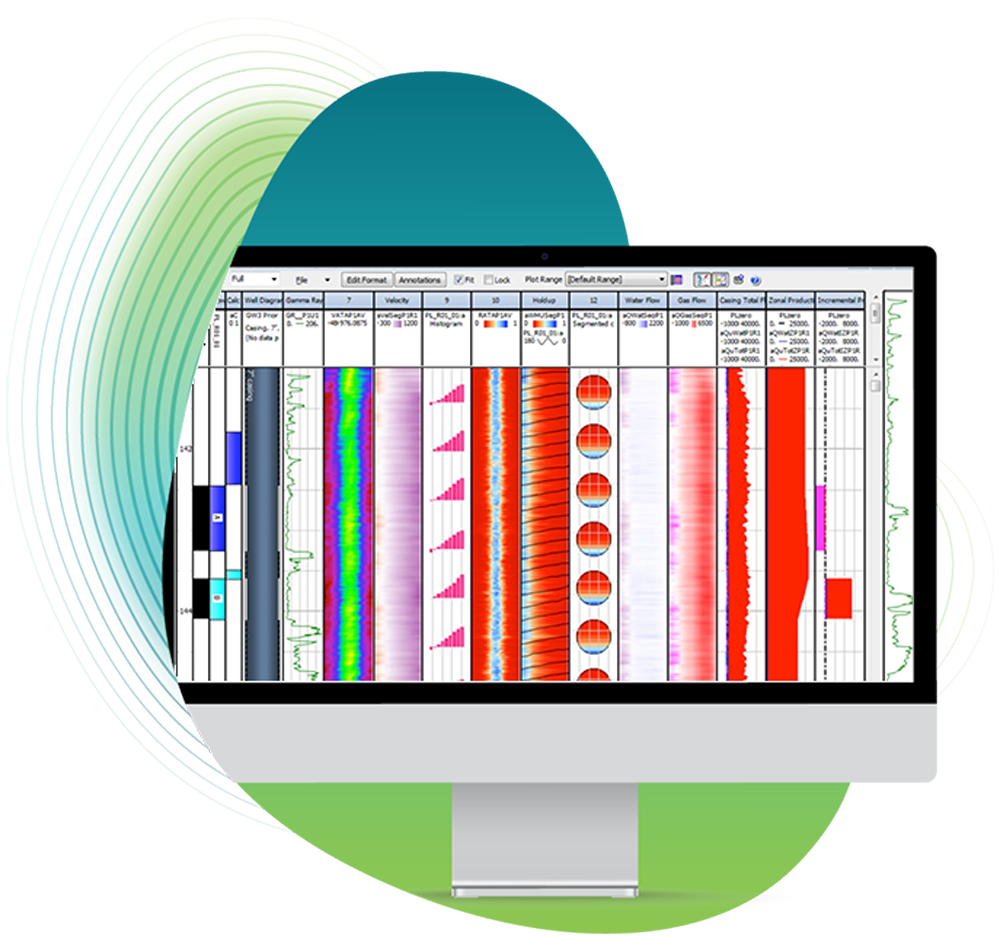

Production Logging

Our Production Logging module gives you an extensive set of tools to organise, edit and analyse a whole variety of Production Log data types. The module helps you spot exactly where production problems lie, so you can target actions to improve productivity and revenue.

Identify downhole producing zones. Quantify their contribution to overall flow.

Calculate gas, water and oil volumes at each reservoir depth. Access a completely new workflow dedicated to PL interpretation in deviated or horizontal wells.

- Specialist tools to import, calibrate and edit PL data

- Calculate multi-phase flow

- Integrate PL with open hole data within IP to enhance understanding

- Cut outsourcing costs by taking control of your own PL interpretation

Pictured: Visualise your production logging data in IP, including cumulative flowrates, zonal contributions and apparent velocities.

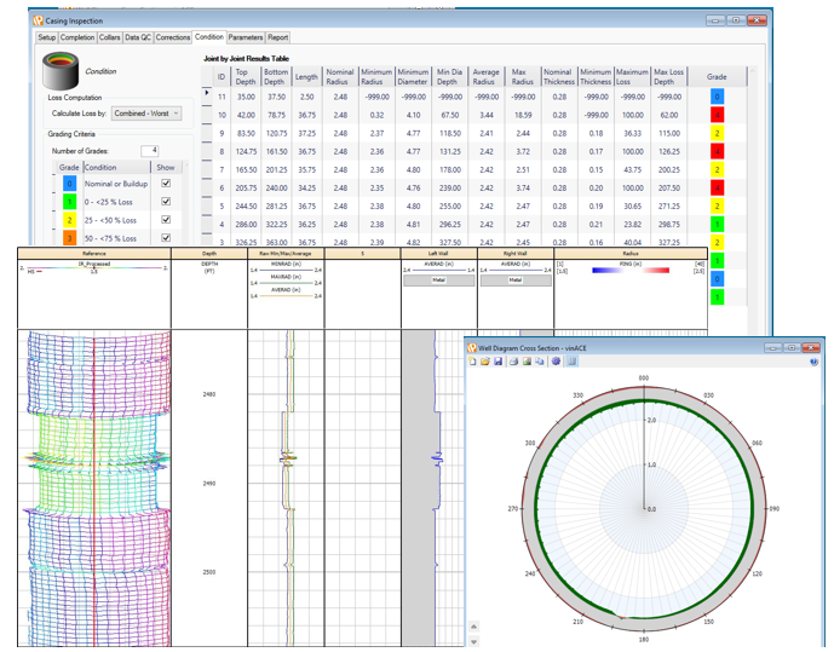

Casing Inspection

The Casing Inspection module allows for inspection and monitoring of downhole pipe condition.

- Uses data from Multi-fingered Imaging Tool (MIT) data and Ultrasonic logging Tools

- Optional import of Thickness Data

- Display data as log plot with interactive, oriented cross section

- Editing and removal of bad data

- Centralize/Normalize data

- Collar Recognition

- Wear/Buildup Statistics

- Joint-by-Joint Condition report

Pictured: Understand the condition of casing using data obtained from a Multi-Finger Caliper tool using our Casing Inspection module.

Explore IP

From porosity and pore pressure to reservoir productivity, IP gives you an incredibly capable and customizable solution to share and interpret well logs and many other vital data types.

Toolkits

IP Foundation

Contains all the tools and modules required for the complete management of subsurface log data including loading, log plots, x-plots, histograms, editing, filtering, depth shifting, exporting etc. Carry out the full, deterministic, petrophysical workflow – Includes Clay Volume, Porosity/Water Saturation, Cut-Off and Summations modules plus NMR Interpretation. Also includes Monte Carlo Analysis for uncertainty analysis, Chrono Log, IP Power Tools and the ability to create you own IP applications.

Advanced Formation Evaluation

Carry out complex interpretations with Mineral Solver, and characterize your reservoir with Saturation Height Modeling, Hydraulic Flow Units, and Formation Testing modules.

Learn More

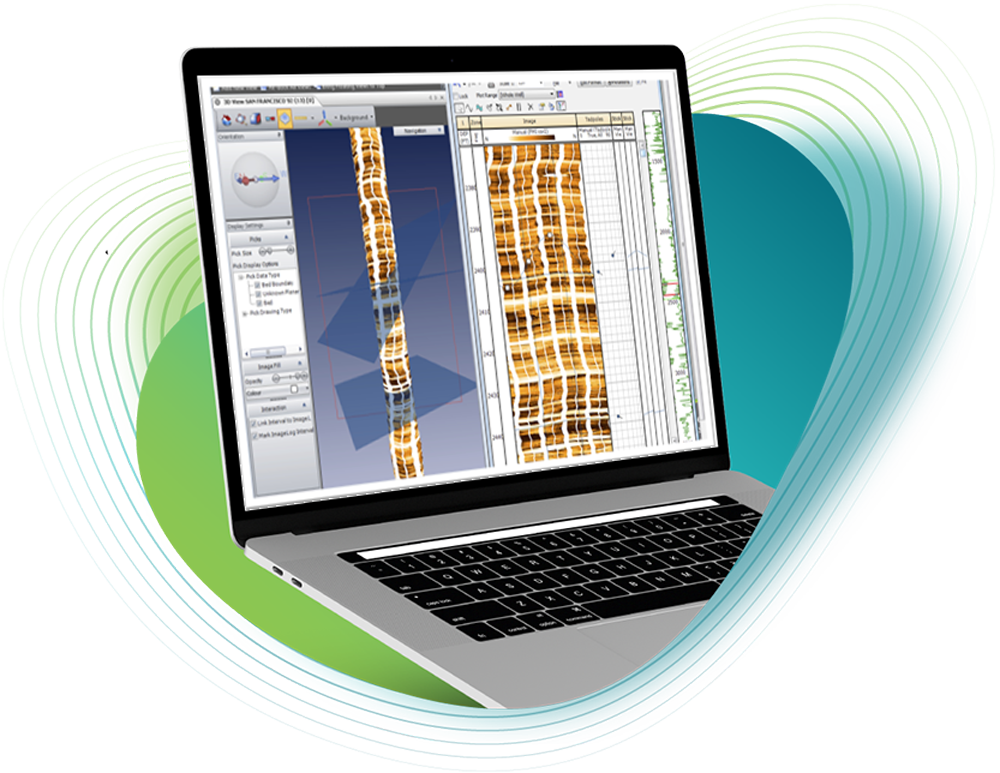

Borehole Imaging

Perform enhancements and corrections to Image Log data, utilize the vast amount of display and interpretation options specifically tailored for all the main image log tool types on the market.

Learn More

Cased Hole

Assess the downhole integrity of your wells with the casing and cement evaluation modules, while also monitoring reservoir fluid saturations and the production performance of each well.

Geomechanics

Assure your well’s stability and maximize production lifetime using our suite of Geomechanics modules. Calculate pore pressures, determine wellbore stability and calculate risk of sand production.

Geophysics

Bring your Petrophysics and Geophysics teams together to calculate the downhole acoustic properties of the formation, carry out fluid substitution analysis and create synthetic seismograms.

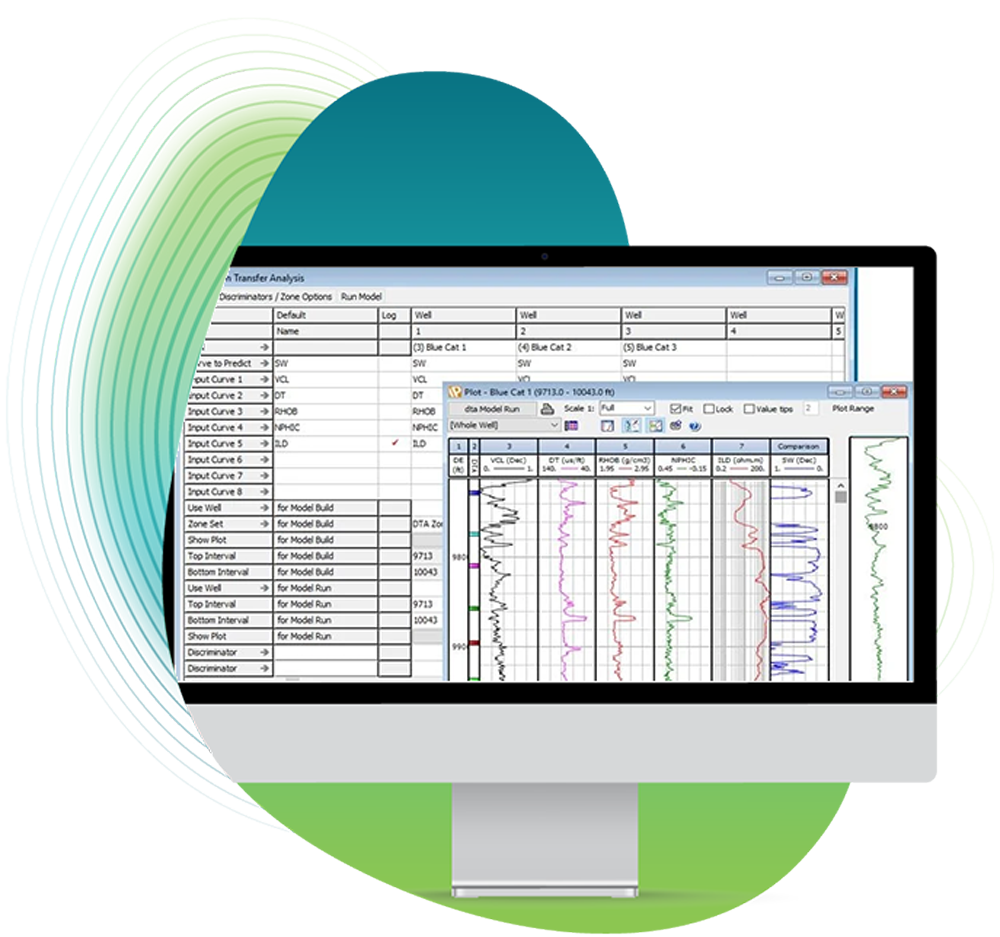

Machine Learning

Carry out data repair, prediction of missing curves, or key reservoir properties using minimal source data. Classify reservoir rock types using Self Organizing Maps and Cluster Analysis.